Description

The equipment does not need to add lubricating oil, and the discharged gas does not contain oil and oil vapor, so it can be protected from pollution, eliminating the need for complex filtration and purification systems, saving equipment costs and maintenance costs, and has significant features such as safety, reliability, and easy operation.

A booster air compressor or compressed air pressure amplifier operates on the simple principle that within a closed system (non-vacuum), the pressure increases as volume decreases. An air booster compression system comprises a receiver tank, pipework,and discharge tank.The receiver tank has an inlet that receives compressed process air coming from a primary feed and channels it through several compression stages to further increase the pressure. Additionally, the receiver tank serves as a limited storage capacity for when the system is not actively delivering compressed air.After going through a series of compression stages, pressurized air flows through the piping into the discharge tank which contains an outlet that supplies the gas to the site.

* Low working pressure and safely.

* Good flexibility. The purity and output for oxygen can be easily adjusted.

* Simple Process And Less Equipment,High Automation And Operation Convenience

* Quick Starting And Easy Stopping, The system can provide product gas in 30 minutes after starting and also can be operated

|

Product Name

|

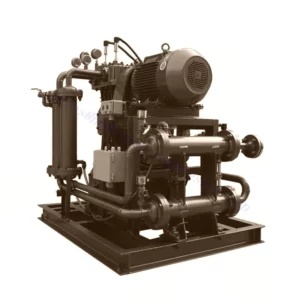

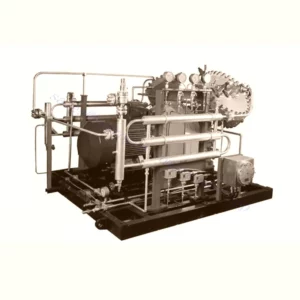

Oil-Free Oxygen Booster compressor

|

|

Cooling Method

|

Air-cooled or water-cooled

|

|

Range Of Rotation

|

300-600r/min

|

|

Power Range

|

<55KW

|

|

Flow Range

|

Support Customization

|

|

Inspiratory Pressure Range

|

0-0.6Mpa

|

|

Exhaust pressure range

|

≤25.0Mpa

|

|

Compression stage

|

3-4Class

|